Our solution:

Innovative product design with future-oriented materials

We are specialists in innovative material solutions that go far beyond the usual standards. Our focus is to develop materials that combine seemingly incompatible properties. These properties include, for example, electrical conductivity, temperature resistance, wear resistance, and many more.

Our contribution creates space for creative further development.

HFM®️

COMO®️ 4-350 HWL

HEL®️55

AR®️25

From the initial idea

to series production

Our partnership starts with your vision. We take the time to understand your challenges. Together, we strive to develop customized solutions that exceed your expectations. From the initial concept to series production, we support you on the road to success.

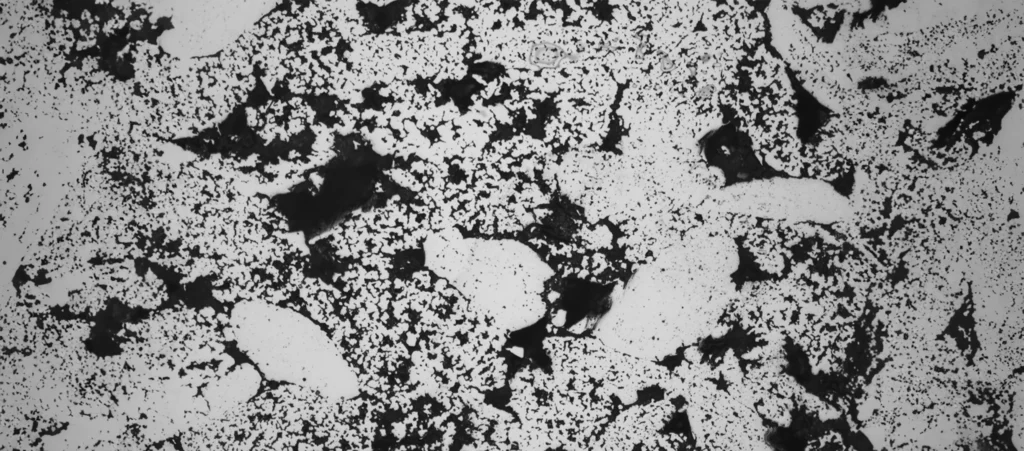

MATERIAL BLENDING

Our materials are carefully blended according to customer requirements and individual formulations. In the process, we observe both the customer’s specifications and processability to ensure high-quality materials. We also provide support for post-processing by the customer if required by determining the correct processing parameters for our materials.

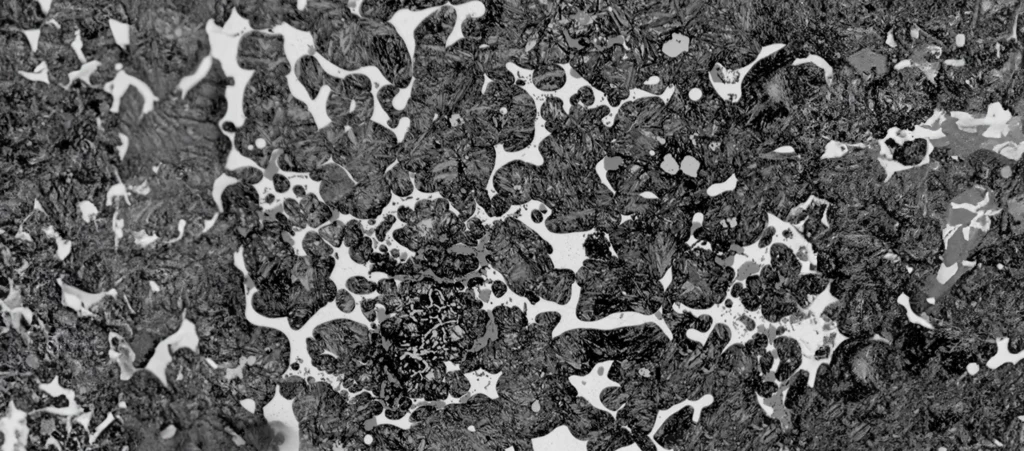

PRESSING

When pressing green compacts, we use pressing tools that are specially adapted to the components and material properties. During the pressing process, so-called green compacts are created. These already have close contour geometries, exact tolerances, and optimum density.

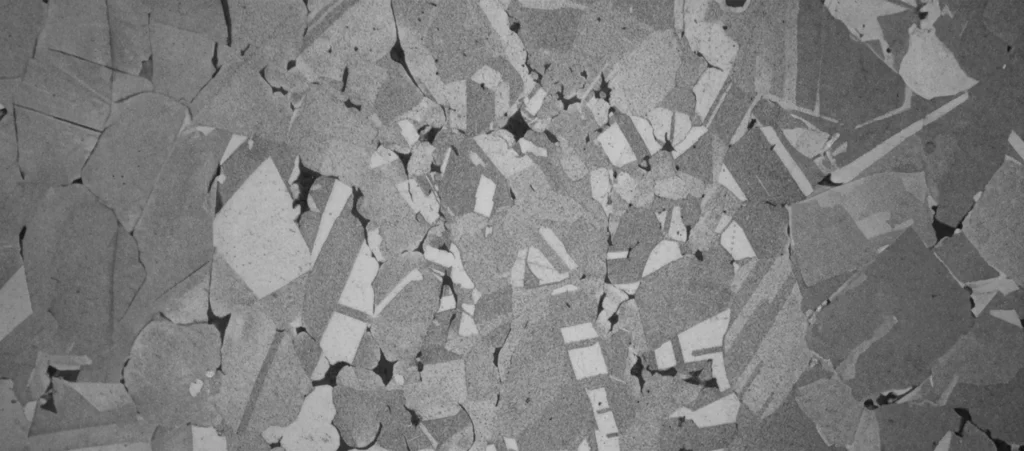

SINTERING

In the sintering production step, precise heat treatment is carried out under a defined atmosphere, temperature, and speed in order to achieve the final material and component properties. This is where the material gains its strength.

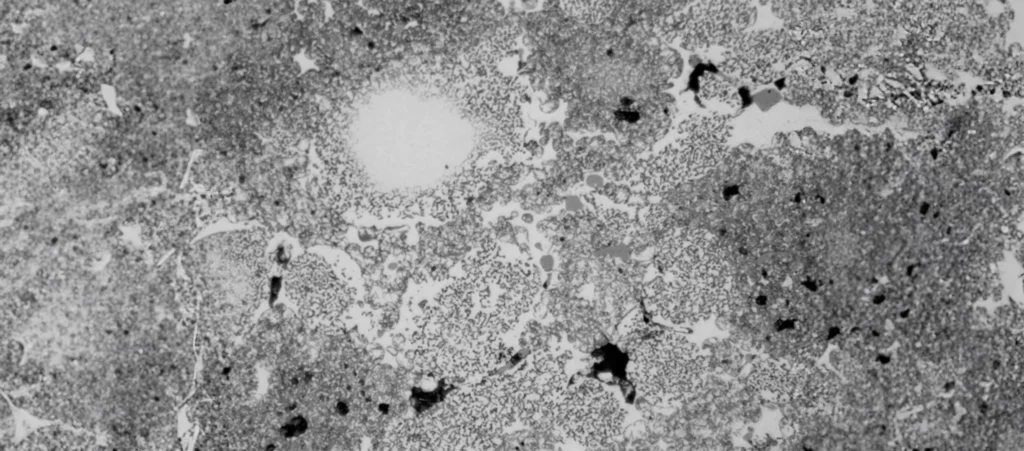

HEAT TREATMENT

Further heat treatment is carried out to fine-tune the final material properties. Each unit is treated individually according to the specific requirements.

MECHANICAL PROCESSING

The mechanical finishing of the products for the final end product may be necessary due to the product requirements and is carried out according to the specifications and tolerances required by the customer.

MATERIAL BLENDING

Our materials are carefully blended according to customer requirements and individual formulations. In the process, we observe both the customer’s specifications and processability to ensure high-quality materials. We also provide support for post-processing by the customer if required by determining the correct processing parameters for our materials.

PRESSING

When pressing green compacts, we use pressing tools that are specially adapted to the components and material properties. During the pressing process, so-called green compacts are created. These already have close contour geometries, exact tolerances, and optimum density.

SINTERING

In the sintering production step, precise heat treatment is carried out under a defined atmosphere, temperature, and speed in order to achieve the final material and component properties. This is where the material gains its strength.

HEAT TREATMENT

Further heat treatment is carried out to fine-tune the final material properties. Each unit is treated individually according to the specific requirements.

MECHANICAL PROCESSING

The mechanical finishing of the products for the final end product may be necessary due to the product requirements and is carried out according to the specifications and tolerances required by the customer.

Our experience stands for itself

Our approach is characterized by structure, transparency, and partnership. At BleiStahl, we see you not just as a customer, but as a partner. Our primary goal is your satisfaction and long-term success.

Shaping Tomorrow together

Together, we can shape the world of tomorrow. Tell us about your challenges, and contact us today!